Sealless Technology

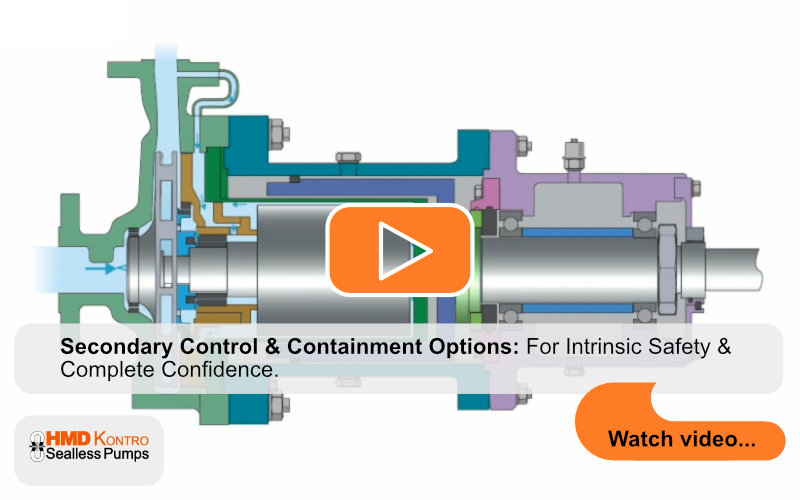

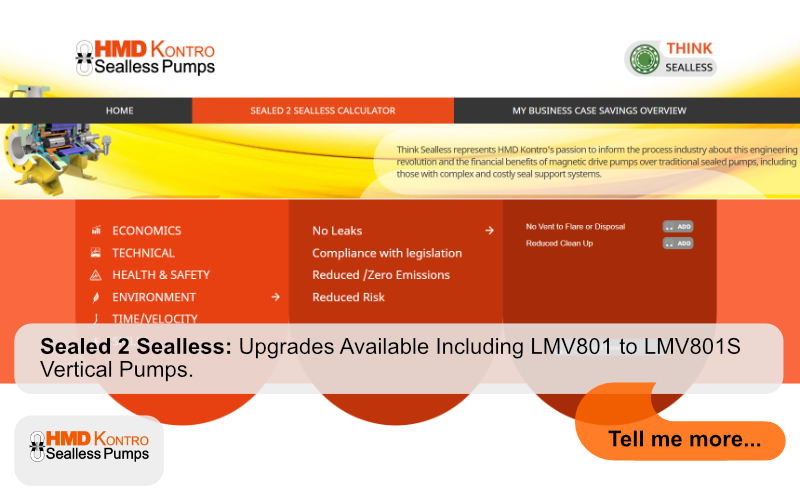

Magnetic drive sealless pumps have many key design features for increased reliability, reduced costs, enhanced safety and environmental friendliness. Sealless pumps save time and cost on design and installation. By specifying an HMD Kontro sealless pump you can be absolutely positive that you have made the right decision.

If your industry involves the movement of hazardous toxic, fine, corrosive and/or aggressive liquids, our pumps deliver solid performance and all are designed to meet stringent industrial regulations including API, ASME, ANSI, DIN and ATEX.

more

About Us

HMD Kontro is recognised as the pioneer of sealless pump engineering and manufacturing. Contact us to discuss how magnetic drive pump technology can save you time and money.

In 1947, the very first sealless magnetic drive pump was developed by HMD Kontro, breaking new ground in pump and fluid handling technology.

moreOur Pumps

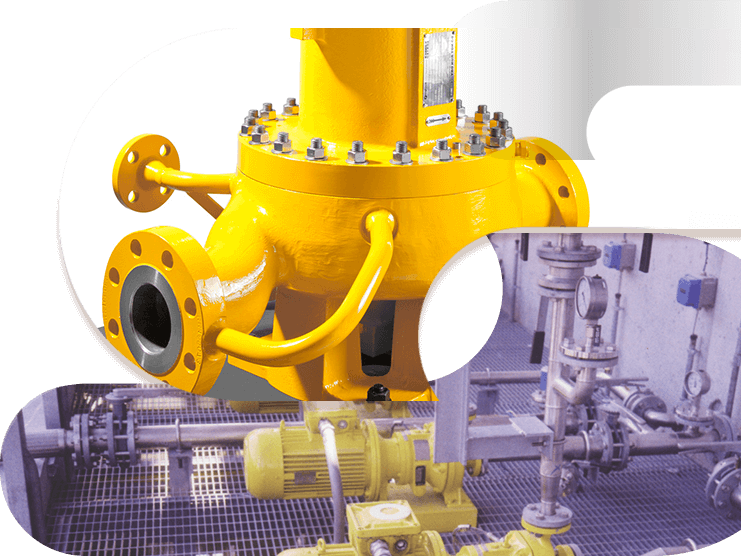

HMD Kontro’s comprehensive range of magnetic drive sealless pumps is designed to perform in the most rigorous of climates and for a variety of applications providing a wide range of benefits and advanced features.

Take a moment to see how our pumps can help revolutionise your process workflow.

more

Recent stories from our blog

New Chemical Industry Brochure

ACHEMA in August